|

Additive Manufacturing: a quick and non-exhaustive technical data sheet

Since not all of us are experts of industrial productive techniques, a few informative notes are necessary. It is simple enough: traditional mechanical manufacturing technologies are called subtractive, since they mostly work on metals by subtracting material. From a round or squared piece, superfluous material is sheared through turning or milling with the support of CAD/CAM tech. I hope experts in mechanical processing technology will forgive me for this extreme simplification, but I just aim to give a general idea to the non-experts. Additive manufacturing—commonly known as 3D printing—operates instead in the opposite way, by adding material where it is needed. This is done by layering material in shapes based on CAD/CAM models. Prime materials are in this case powders from metal or other materials, then mixed with additives to obtain alloys and compound materials. The powders are then melted with lasers or other heat-based methods, following the outline of the digital model. 3D printing can also be used to create objects starting from polymers or polymeric alloys. Precision additive manufacturing is divided in a few sub-technologies. I will list here the ones I was able to note down: EBM (Electron Beam Melting), DMLS (Direct Metal Laster Sintering), SLM (Selective Laser Melting), SLS (Selective Laser Sintering), LBW (Laser Beam Welding), FDM (Fused Deposition Modeling).

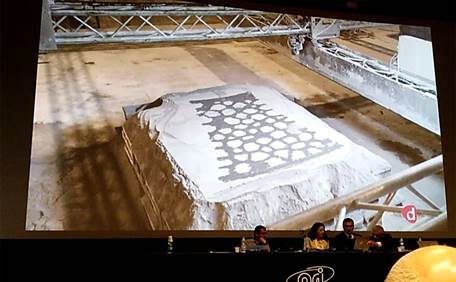

Large scale 3D printing, presented by its inventor Enrico Dini (D-SHAPE), utilizes sand mixed with chemical binders, and obtains a compound similar to rock. This is used to build habitable facilities and a variety of different elements—including artificial coral reefs to repopulate ocean floors. Since 2010, ESA has been experimenting with this technology to “print” habitable modules on the lunar surface, using regolith as construction base material. For more on this, see the famous videos of architect Norman Foster, one of the partners in the D-SHAPE team.

As widely discussed during the workshop, these are technologies destined to radically change the ways of industrial production. Or maybe we could say—if by industrial production we mean the tayloristic model of serial factory, or its modern adaptation, the robotic islands—that these technologies are destined to embody the ways of post-industrial production. Of course, for mass production purposes, serial production chains will continue to exist. But the most important aspect that seems to have reached its end—or at least to be significantly reduced—is the paradigm of economies of scale: “the larger the volume the lower the production cost”. This is because 3D printers allow to drastically lower the production costs for small or very small series as well.

The advantages of additive production, compared to subtractive, are plenty and, as revealed during the workshop itself, many of them are yet to be discovered. Here, in random order, are the ones I was able to capture from the slides shown by workshop participants. Through additive manufacturing, it is possible to create geometries and structural properties that would be impossible to create with traditional processes. It is possible to create components of incredible geometric complexity. It also becomes exponentially easier to customize production, even for low volumes. 3D printing allows for a great reduction of the number of components needed to make up an object—if not, in many case, for the production of a single shaped piece. Prototyping and production times are also much shorter, compared to traditional techniques. The finished product is much more durable, resilient, and compact, thanks to the substantial absence of mechanical stress—which in classic processing happens due to “violent” processes such as turning, milling, bending. Also, the finished pieces tend to be significantly lighter in weight. Last, but not least, additive manufacturing definitely presents itself as a “green” technology—or, in other words, sustainable. The saving of material and waste reduction are huge: just consider that the leftover powders not used in the process are not ruined or modified in any way, and can therefore be reused in the process for a very high number of cycles. At the same time, there is a great reduction of environmental pollution, both through the production process, through the massive reduction in transport and logistics activities, and also through saving of material. Compared to traditional foundry, we have less use of energy, and no emission of toxic waste, such as dioxins, etc.

Mechanics is not “mechanic” anymore

As noted by the various speakers at the workshop, and in particular by Professor Quadrini, from Tor Vergata University, the shapes of the objects developed through AM are very different from the shapes—usually squared or roundish—of traditional mechanical products. They resemble more closely the organic shapes of nature instead: bones, trees, seashells. Through opportune study of the structural characteristics of certain natural shapes, it will be then possible to create 3D printed components with similar qualities of flexibility and durability. For those endowed with artistic sense, 3D printed shapes are very stimulating tools, and it’s not difficult to imagine an age that will inspire artists as much as the futurism-mechanics duo did for the great artistic movements of the past century. Let’s forget terms such as beams, clamps, pillars, and let’s adopt words maybe a little more disquieting, because they resonate with our own biology—for example trabecula. These terms make us think of future blends between medical science and mechanical engineering, and not only on obvious common grounds such as robotics and cybernetics.

As noted by the various speakers at the workshop, and in particular by Professor Quadrini, from Tor Vergata University, the shapes of the objects developed through AM are very different from the shapes—usually squared or roundish—of traditional mechanical products. They resemble more closely the organic shapes of nature instead: bones, trees, seashells.

A.M. and space development

Up to here, we have been talking about a new technology, certainly revolutionary and fit for the renaissance—yet definitely confined to terrestrial purposes. Additive manufacturing, as Professor Quadrini himself observed, works by stratification, in a vertical direction, depending heavily on the force of gravity. It is therefore limited, at least for now, to terrestrial applications. In just a few instances—Loredana Santo from Tor Vergata University, Maurizio Romeo from BEAMIT—the discussion verged on 3D printing techniques in microgravity conditions, that could be tested aboard the ISS. Why, then, the strong interest shown by ESA and ASI for this technology? First of all, we must not forget, for the time being the main focus of most companies is still satellite activities. However, the wind is definitely changing, as demonstrated by the strong interest towards the Moon shown by ESA after the assignment of the new general Director Johann-Dietrich Wörner, and by Professor Roberto Battiston’s speech at the end of the workshop. We wait with bated breath for these promising intentions to be translated into actual Intended Tenders. Nevertheless, it is still an important step forward that ESA started a great mediatic outreach, on a true expansion programs.

The production of components using A.M. techniques is already started, and in the aeronautical field 3D printed components have been flying for a while now. In the space field, Space X employs 3D printed valves on the Falcons, and the Super-Draco engine is equipped with an entirely 3D printed combustion chamber. Nowadays additive technologies allow to significantly reduce launch costs for all components, from launchers—much cheaper—to payloads (satellites). It will be possible to design, prototype, and produce everything at least one order of magnitude faster; it will also weight less, and cost less, reducing as well the constricting requisite of high durability of space components. When missions used to cost a billion, it was inevitable to rely on fully established technologies, thus neglecting innovation. As remarked by Mauro Varetti—CEO of 3D-NT, ambitious Turin-based startup—additive techniques will open the aerospace field to experimentation, without skipping on reliability requisites—especially when missions include human beings. All of this would be hard to even imagine if Elon Musk had not knocked down launch costs from the 900 million standard—maintained for so many years by United Launch Alliance—to 60 millions, even before the coming of entirely reusable rockets. It is predicted that, when the process of reuse will be established, launch cost will settle around 500.000 dollars.

Up to here, we have been talking about a new technology, certainly revolutionary and fit for the renaissance—yet definitely confined to terrestrial purposes.

Potential of AM for the development of civilian astronautics

The potential of AM is even greater. There is, in fact, the possibility of reducing the cost of launching satellites into orbit almost down to zero, at least for launching from Earth. We can imagine a series of orbital production facilities, using lunar and asteroidal raw materials reduced to powder. The powder would be produced through factories, installed at the lunar poles and at the Lagrange points. The designs for satellite parts and others will be transmitted from Earth, and produced by 3D orbital factories. Astronaut technicians will assemble the satellites and, through suitable interorbital vehicles, they will take them to their destination; technicians would also be responsible for maintenance and, at the end of satellites’ life cycle, for decommissioning. In time, the space infrastructure will be able to sustain its production using only extraterrestrial resources. Satellites will be rid of the expensive and sophisticated automated components—expensive because of the robustness required by launch stress—currently used to unfold solar panels and antennas.

Of course, as soon as entrepreneurs will start to populate the geo-lunar space—together with researchers, inventors, and technicians—industrial activity will not be limited to satellite components anymore. It will naturally extend to all the areas that sustain terrestrial civilization, and probably much more will bloom into the human mind as soon as it will be able to think—in 3D!—outside of Earth’s gravitational well.

|

Space Renaissance France (French Chapter of SRI)

Space Renaissance France (French Chapter of SRI)  Space Renaissance USA, Inc. (USA Chapter of SRI)

Space Renaissance USA, Inc. (USA Chapter of SRI) Space Renaissance (Italian Chapter of SRI)

Space Renaissance (Italian Chapter of SRI) Space Renaissance Academy

Space Renaissance Academy Space Renaissance Initiative Group

Space Renaissance Initiative Group